Transformer Coil

Copper coil is the key component of each transformer, inductor or choke. The step up & down transformer needs coils to operate internally. The transformer coil winding is used to transfer energy from the power supply to the load and help filter the circuit. They can also provide critical isolation for equipment from the source.

Coil Form of Transformer:

Coils are usually divided into layer type and cake type two. Coil turns along the axis according to the layer arrangement of continuous winding system, called layer coil. Each layer is like a cylinder, which is to consider the coil has better mechanical strength, not easy to deform and easy to wind. The coil composed of two layers is called double layer cylinder type, a multilayer is called a multilayer cylinder. Coil turns along the radial continuous wound into a wire cake (line segment), and then by a number of wire cake along the axial arrangement of the coil called the cake coil. Such as continuous, tangled coil are such coil form.

Coil Capabilities:

We design transformer coils with a vast range of capabilities. Some of these include, but are not limited to:

- Cylindrical wound square, round or rectangular copper wire for low voltage with multiple windings, layers and taps.

- Copper foil windings for low-voltage high-current applications.

- Raising or lowering the voltage levels in AC or DC circuits.

- Isolate critical loads from the source.

Advantages of Transformer Coil:

We have improved our systems and processes to ensure that you are satisfied with our transformers and services. There are some advantages of our transformer coils:

- Automation. Our factories are equipped with the most advanced equipment. It also greatly improves the safety of production.

- Quality. We are a standard certified transformer transmanufacturer. Our processes, personnel, equipment maintenance, and instrumentation controls follow strict quality standards.

- Quick Turnaround Times. We are committed to saving your time and money, maintaining a large number of materials in stock, and rapidly producing various transformers and coils.

- Customer Relationships. We have built long-lasting relationships by working with our customers to satisfy every requirement.

Transformer Test

The power transformer is the core of the power system in the power industry. The key to the safe operation of the power system is that the transformer is not damaged, so it is essential to test the transformer regularly. In the daily maintenance work of transformer, it is necessary to monitor the running condition of step up down transformer in real time, especially in overload operation, but also to shorten the monitoring cycle.

A transformer is an electrical element that transmits electrical energy between at least two circuits. The transformer regulates the voltage in the circuit, but in some cases, these may cause the circuit to fail to work. You need to determine the key information about the transformer, such as whether it has suffered visible damage, and what its input and output are.

1. Identifying Key Information of Transformer

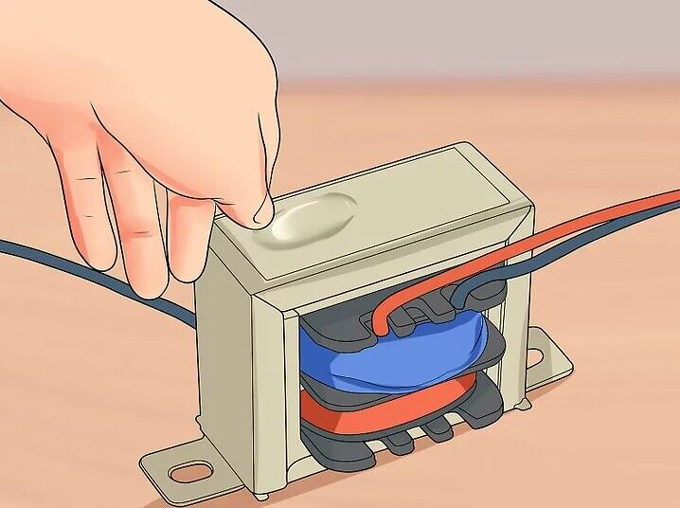

- Visually inspect the transformer. Overheating will cause the internal wiring of transformer to operate under high temperature, which is a common cause of transformer failure. This usually results in physical deformation of the transformer or its surrounding area.

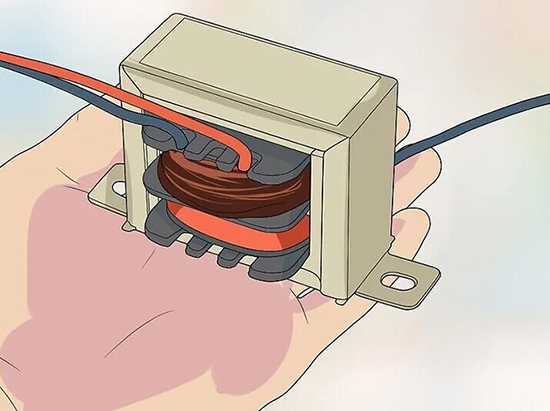

- Determine the wiring of the transformer. The wiring on the transformer shall be clearly marked. However, it is better to obtain the circuit schematic diagram containing the transformer to determine how it is connected.

- Identify transformer inputs and outputs. The first circuit will be connected to the primary circuit of the transformer. This is its electrical input. The second circuit that receives power from the transformer is connected to the transformer secondary or output.

- Determine the output filtering. It is common to attach capacitors and diodes to the transformer secondary to convert the AC power from the output to DC power.

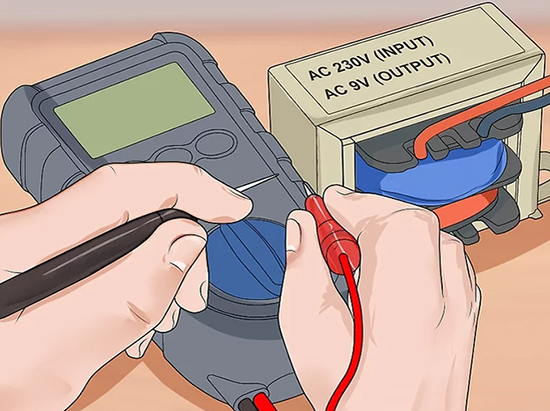

2. Testing it with a Digital Multimeter

- Prepare to measure the circuit voltage. Cut off the power supply of the circuit. Remove the cover and panel as necessary to access the circuit containing the transformer. Prepare a digital multimeter (DMM) to record the voltage reading. (Generally, you'll need to attach the leads of your digital multimeter to the input lines to verify that the primary of the transformer is not shorted. The same process will be used to check the transformer secondary.)

- Confirm the correct input of the transformer. Apply power to the circuitry. Using digital multimeter to measure the transformer once in AC mode. If the measured voltage is less than 80% of the expected voltage, the fault may be in the transformer or the circuit supplying the primary power supply.

- Measure the secondary output of the transformer. If there is no filtering or shaping being performed by the secondary circuitry, use the AC mode of the digital multimeter to read its output. If there is a DC scale, please use the DC scale of digital multimeter.

3. Troubleshooting Your Step Up & Down Transformer

- Understand the root of the problem. A step up and down transformer fault is usually a symptom of another fault somewhere in the circuit. Transformers generally have a long life and seldom burn themselves out, such as toroidal transformer.

- Observe replaced transformer. If the problem causing the transformer short circuit comes from other parts of the circuit, the transformer is likely to burn out again. After replacing the transformer, observe it to ensure that this does not happen. If so, additional tests need to be performed.

- Verify the condition of external fuses. If your step up and step down transformer has an internal fuse, there may be no fuse on the line to the transformer. Otherwise, there should be fuses on the power supply line of the transformer. Check to ensure that these are in good condition, and replace any that cannot work properly.

- Remove inputs and outputs to determine the source of the failure. For linear fuses, you have only one input and output. In this case, the problem comes from either the input circuit or the output circuit. For more complex fuses, remove the input and output of the step up and down transformer one by one to determine which component of the whole circuit causes the short circuit.

Transformer Troubleshooting

Power transformer is the main equipment in the distribution network, and also the main equipment to supply power in industry, agriculture and residential electricity. However, in daily production, there will always be a variety of problems leading to transformer damage or can not be used normally.

In order to reduce the probability of step up and step down transformer failure and improve the reliability of power supply, steptransformer.com will analyze the common failure types and failure causes of distribution transformers in the power system, and put forward corresponding preventive measures to reduce the failure of transformers.

- Temperature anomaly. The cause of this kind of failure is mainly the fault of the transformer winding. During the manufacturing or maintenance of a power transformer, the local insulation is damaged and the remaining defects are left. In operation due to poor heat dissipation or long-term overload, sundries in the winding fall into, so that the temperature is too high.

- Sound anomaly. The core emits a uniform "buzzing" sound due to the electromagnetic force generated by alternating magnetic flux passing through it. When the transformer emits a "crackling" sound, it may be the insulation of the winding or the iron core is broken down, or the live conductor such as the lead wire is too small to discharge from the tank or the iron core.

- Three-phase voltage imbalance. The cause of the three-phase voltage imbalance may be because the staff unreasonable distribution of three-phase load resulting in light load phase voltage increase, heavy load phase voltage decrease, current increase, eventually lead to the transformer turns between short circuit, burnt transformer, especially isolation power transformer.

- High-voltage fuse is blown. One reason for this kind of failure is that with the continuous development of social economy, power consumption increases rapidly, the original step up step down transformer capacity is small, resulting in transformer overload operation. Or seasonal climate causes peak power consumption, so that the transformer overload operation. The resulting high temperature will lead to insulation aging, paper strength reduction, resulting in insulation damage, and then failure.

- Oil leakage. Transformer oil leakage is mainly due to the long-term operation of the transformer, the sealant pad at the connection point aging and cracking, resulting in oil seepage, so that the insulation oil moisture absorption, resulting in the decline of insulation performance. Or because the product quality of the gasket itself is not up to standard, poor welding quality, installation process and installation operation is not standard and equipment structure is unreasonable and manufacturing problems and so on.