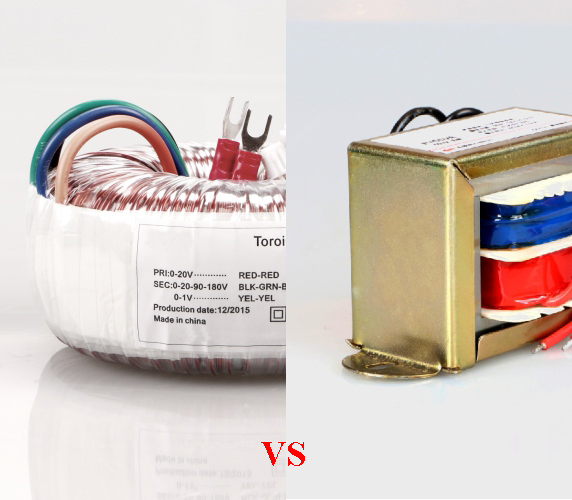

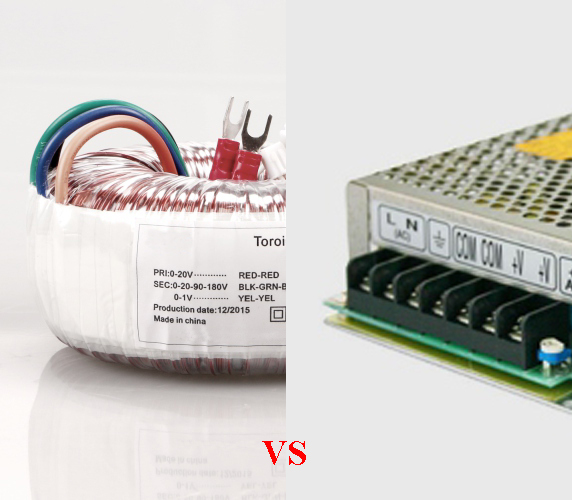

A toroidal transformer uses a toroidal (doughnut-shaped) core made of

ferromagnetic material, such as iron or ferrite. It is commonly used in

various applications, including voltage

converters.

In the context of a 220V/110V voltage converter, a toroidal transformer

is used to step down or step up the voltage. A step-down transformer is

used when converting from a higher voltage (220V) to a lower voltage

(110V), while a step-up transformer is used when converting from a lower

voltage (110V) to a higher voltage (220V).

The primary winding of the toroidal transformer is connected to the

input voltage (220V), and the secondary winding is connected to the

output voltage (110V). The number of turns in the primary and secondary

windings determines the voltage ratio of the transformer. For example,

if the primary winding has twice as many turns as the secondary winding,

the transformer will step down the voltage by a factor of 2.