Single Phase Isolation Transformer

- Dry type

- 500 VA-30 kVA

- 0V-690V

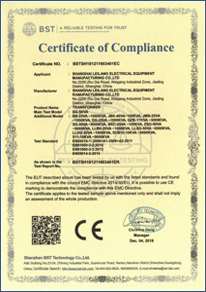

Wholesale price safety isolating transformers, manufactured in China, with capacities ranging from 5 kVA to 1000 kVA, can be used as step-up or step-down transformers, converting voltages from single-phase to single-phase and three-phase to three-phase. Whether you are looking forward to buying isolation transformer equipment from a reliable Chinese manufacturer, electrical isolation transformers, or any type of custom isolation transformer, let us know your requirements, and we will create a new design to meet your form and function specifications.

Cold rolled oriented silicon steel sheet with good heat dissipation, low loss core and good magnetization characteristics.

The back of the transformer installed cooling fan, can be strong and effective heat dissipation, reduce the temperature of the machine.

The Isolation transformer with

180°C high temperature enameled wire, is not easy to

oxidation, and has stable performance.

The excellent insulating paper enables the isolation transformer to withstand a 3000V withstand voltage test, enhancing safety.

Manufactured with removable wheels, the power isolation transformer can rotate 360 degrees, making it more energy-saving when pushed.

1. Determine

the transformer specifications: Customize an isolation transformer that meets the power

requirements of the equipment you are trying to protect. Consider voltage, current rating and supply frequency, ensure that the transformer is manufactured in compliance with industry standards.

1. Determine

the transformer specifications: Customize an isolation transformer that meets the power

requirements of the equipment you are trying to protect. Consider voltage, current rating and supply frequency, ensure that the transformer is manufactured in compliance with industry standards. 2. Verify

the transformer's condition: Please check the 1/3 phase isolation

transformer for any signs of physical damage or wear. Since the transformer is shipped directly from the factory in China, please check whether the isolation transformer is intact after receiving the goods.

2. Verify

the transformer's condition: Please check the 1/3 phase isolation

transformer for any signs of physical damage or wear. Since the transformer is shipped directly from the factory in China, please check whether the isolation transformer is intact after receiving the goods. 3. Disconnect the

power supply: Safety is paramount; before connecting or disconnecting the isolation transformer, ensure that the power to the connected equipment is switched off and unplugged from the main socket to prevent any electrical hazards.

3. Disconnect the

power supply: Safety is paramount; before connecting or disconnecting the isolation transformer, ensure that the power to the connected equipment is switched off and unplugged from the main socket to prevent any electrical hazards. 4. Connect the

primary side: The primary side

of the isolation transformer is connected to the power source. Connect the input

terminals of the transformer to the power supply lines. Ensure that the

connections are secure and properly tightened.

4. Connect the

primary side: The primary side

of the isolation transformer is connected to the power source. Connect the input

terminals of the transformer to the power supply lines. Ensure that the

connections are secure and properly tightened. 5. Connect the

secondary side: The secondary

side of the transformer is connected to the equipment you want to protect.

Connect the output terminals of the transformer to the input terminals of the

equipment. Ensure that the connections are secure.

5. Connect the

secondary side: The secondary

side of the transformer is connected to the equipment you want to protect.

Connect the output terminals of the transformer to the input terminals of the

equipment. Ensure that the connections are secure. 6. Power on the transformer: After all connections have been made, turn on the

isolation transformer with care to ensure that the input voltage exactly matches

the rated voltage of the transformer.

6. Power on the transformer: After all connections have been made, turn on the

isolation transformer with care to ensure that the input voltage exactly matches

the rated voltage of the transformer. 7. Power on the

equipment: Once the isolation

transformer has been energised, you can turn on the device connected to its

output terminal and then verify if the device is functioning properly. Do

not forget to verify that the device is operating correctly.

7. Power on the

equipment: Once the isolation

transformer has been energised, you can turn on the device connected to its

output terminal and then verify if the device is functioning properly. Do

not forget to verify that the device is operating correctly. 8. Monitor and

troubleshoot: During

operation, monitor the equipment for any unusual behavior, such as fluctuations

in voltage or irregularities. If you notice any issues, disconnect the equipment

from the isolation transformer and troubleshoot the problem.

8. Monitor and

troubleshoot: During

operation, monitor the equipment for any unusual behavior, such as fluctuations

in voltage or irregularities. If you notice any issues, disconnect the equipment

from the isolation transformer and troubleshoot the problem. 9. Power off and

disconnect: Switch off the

device and then the power supply to the transformer. Afterwards, disconnect the

appliance from the transformer and finally disconnect the primary side of the

transformer from the power supply.

9. Power off and

disconnect: Switch off the

device and then the power supply to the transformer. Afterwards, disconnect the

appliance from the transformer and finally disconnect the primary side of the

transformer from the power supply.