The common ratings of 3 phase isolation transformers can vary depending on the

specific application

and the country or region where they are used. Here are a few common ratings for 3

phase isolation

transformers:

-

Power Rating: The power rating of 3 phase isolation transformers is

typically expressed in

kilovolt-amperes (kVA) or megavolt-amperes (MVA). Common power ratings

include 5 kVA, 10

kVA, 25 kVA, 50 kVA, 100 kVA, 250 kVA, 500 kVA, 1 MVA, 5 MVA, etc. Higher

power ratings are

also available for industrial and utility-scale applications.

-

Voltage Rating: The voltage rating of a 3 phase isolation power transformer

refers to the

maximum voltage that it can handle. Common voltage ratings include 208V,

240V, 480V, 600V,

2.4 kV, 4.16 kV, 6.6 kV, 11 kV, 13.8 kV, 33 kV, etc. The specific voltage

rating depends on

the requirements of the electrical system in which the transformer will be

used.

-

Frequency: 3 phase isolation transformers are designed to operate at

specific frequencies.

The most common frequency ratings are 50 Hz and 60 Hz, which correspond to

the standard

power system frequencies in different regions of the world.

-

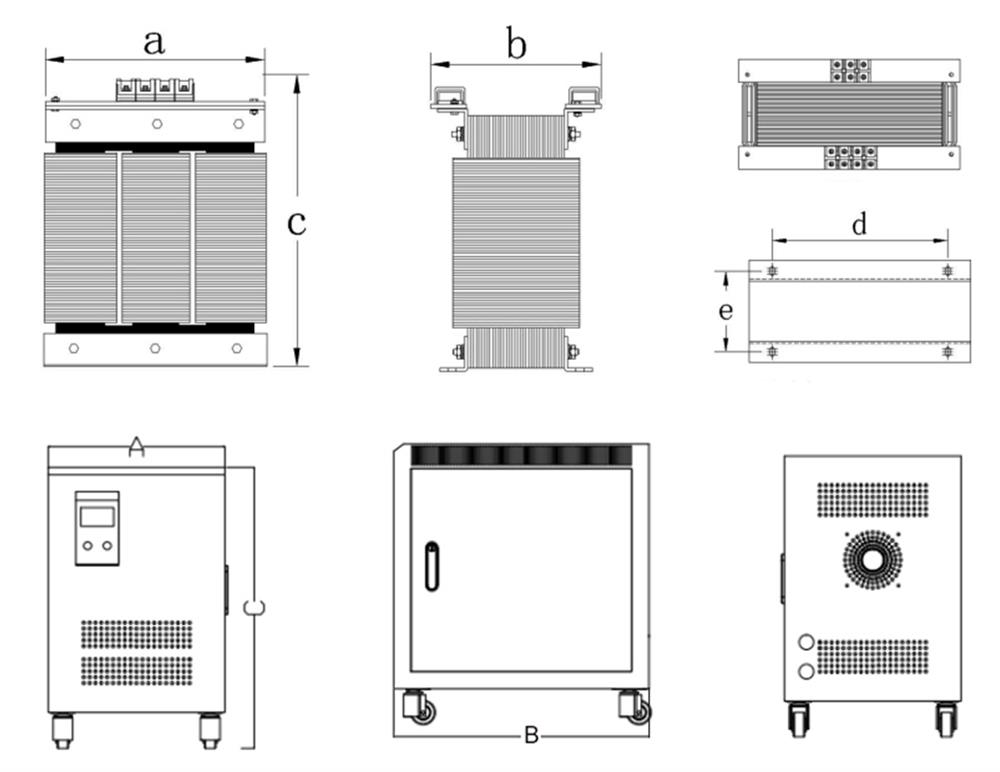

Cooling Method: Transformers may have different cooling methods, such as

air-cooled or

liquid-cooled. The cooling method affects the transformer's ability to

dissipate heat

generated during operation and can vary based on the transformer's power

rating.

These are just some common ratings for 3 phase isolation transformers. It's

important to consult

with our qualified electrical engineer to determine the appropriate ratings for your

specific

application, as requirements can vary based on factors such as load, voltage,

current, and

environmental conditions.