Split Phase Isolation Transformer, 1 kVA to 30 kVA

We are committed to producing high-quality split-phase isolation transformers with a capacity range up to 30KVA. Split-phase isolation transformers undergo strict quality control and testing to ensure compliance with international standards and specifications. Whether used for power transmission and distribution, or powering electronic equipment, our split-phase transformers provide a stable and reliable energy conversion solution.

Specification

| Model | ATO-DGS |

| Phase | Single phase to split phase |

| Capacity | 1 kVA to 30 kVA (customized) |

| Primary Voltage | 1 Phase / 2 phase 110 to 480V (customized) |

| Secondary Voltage | 110V-480V (customized) |

| Frequency | 50/60Hz |

| Winding Material | Aluminum/copper wire (customized) |

| Work Efficiency | ≥95% |

| Insulation Resistance | ≥50 MΩ |

| Electrical Strength | 2000V AC/1 min |

| Noise | ≤35dB (1 meter) |

| Insulation Grade | Grade B (130℃), Grade F (155℃), Grade H (180℃) |

| Cooling Method | Natural or air cooling |

(Note: If you want to know more about split phase isolation transformer specification, please check in catalogue.)

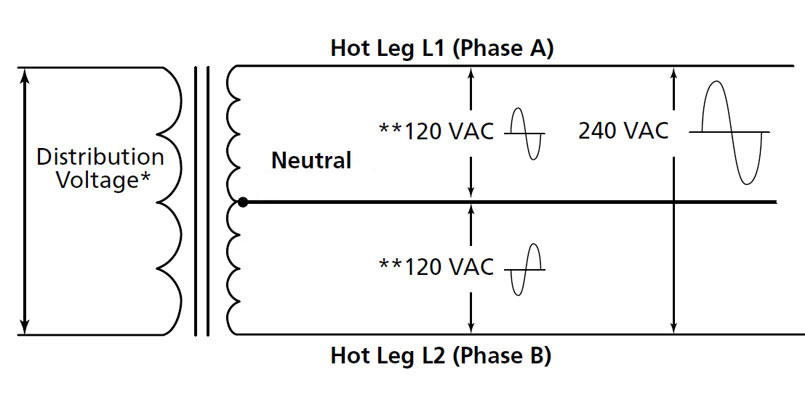

Schematic Diagram

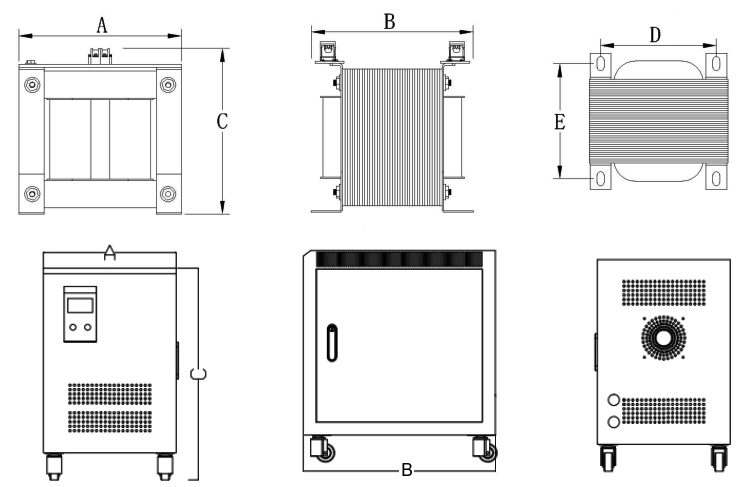

Dimension

Aluminium Wire Transformer Size

- Open type: a*b*c=240*240*260mm

- Mouting size: D*E=180*170mm (aperture: 20*10mm)

- Protected type: A*B*C=300*440*500mm

Copper Wire Transformer Size

- Open type: a*b*c=240*230*260mm

- Mouting size: 180*160mm (aperture: 20*10mm)

- Protected type: A*B*C=380*530*560mm

Advantages

Quality Assurance

Excellent Material

Fast Delivery

Multiple Models

Great Service

Split Phase Isolation Transformer Features

- Scientific and reasonable design, the voltage variation rate is controlled within 1-1.5%.

- Split phase isolation transformer is made of high quality new silicon steel sheet, which can effectively reduce iron loss and improve efficiency.

- The transformer is made of high temperature resistance and high quality wire, which greatly improves efficiency.

- Class H insulation, high temperature resistant insulation material, improves the high pressure strength, prolongs the service life.

- The isolation transformer has beautiful appearance design, large power density, small volume and high space utilization rate.