Copper Coil

Temperature resistance can reach 150 ℃, good insulation and durability, further enhancing the life of autotransformer. high electrical conductivity, excellent heat transfer properties, resistance to corrosion and easy recyclability.

An autotransformer is a type of electrical transformer that has a single winding and operates by using a portion of that winding as both the primary and secondary winding. Autotransformers have the capability to supply a varying secondary voltage to an externally connected load. Customize 1kVA to 100kVA 3 phase auto transformers are mostly used to provide tapped lower starting voltages to motor loads, so they can prevent the motor from the high starting current. We manufactures 3 phase autotransformers in our China facilities which ensure superior quality, trouble free performance, and long working life.

| Model | ATO-T-ASG |

| Phase | 3-Phase |

| Capacity | 1 kVA to 100 kVA (customized) |

| Input Voltage | 0V to 1140V (customized) |

| Input Current | 2A to 151A |

| Output Voltage | 0V to 1140V (customized) |

| Frequency | 50Hz/60Hz |

| Winding Material | Aluminum wire, copper wire |

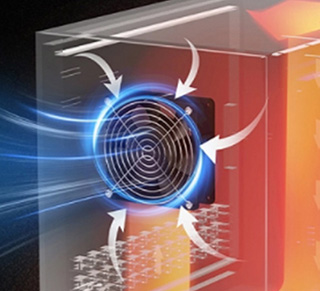

| Cooling Method | Self-cooling or wind-cooling |

| Working Efficiency | ≥98% |

| Protection Grade | IP21 |

| Moisture-Proof Type | Open type, sealed type |

Temperature resistance can reach 150 ℃, good insulation and durability, further enhancing the life of autotransformer. high electrical conductivity, excellent heat transfer properties, resistance to corrosion and easy recyclability.

Manufactured with excellent quality silicon steel, boasting good magnetic flux performance and high heat dissipation properties, it further improves the overall efficiency of the autotransformer.

Stable performance and anti-loosening of tinned terminals with good airtightness and corrosion resistance. Rail-type wiring port, convenient wiring, to ensure that the energized overload capacity.

All-round heat dissipation, not only reduce the working temperature of the autotransformer, but also to extend the service life. Cooling fan reducing energy losses and increasing efficiency by facilitating better heat transfer.

1. Understand the autotransformer:

Familiarize yourself with the specifications of auto transformer, ratings,

and its purpose in the electrical system. Ensure you have the necessary

knowledge and experience to work with it.

1. Understand the autotransformer:

Familiarize yourself with the specifications of auto transformer, ratings,

and its purpose in the electrical system. Ensure you have the necessary

knowledge and experience to work with it. 2. Review safety

precautions: Before starting

work, review the safety guidelines for working with appropriate electrical

equipment. Ensure you have protective equipment and follow all safety procedures

to prevent accidents.

2. Review safety

precautions: Before starting

work, review the safety guidelines for working with appropriate electrical

equipment. Ensure you have protective equipment and follow all safety procedures

to prevent accidents. 3. Verify the

suitability: Ensure that the

autotransformer is the appropriate choice for your application. Confirm that it

can handle the voltage and current requirements of the system without exceeding

its ratings.

3. Verify the

suitability: Ensure that the

autotransformer is the appropriate choice for your application. Confirm that it

can handle the voltage and current requirements of the system without exceeding

its ratings. 4. Inspect the autotransformer:

Perform

a visual inspection of the autotransformer to check for any visible damage,

loose connections, or signs of wear. If you notice any issues, do not proceed

with the installation or operation and contact a qualified technician.

4. Inspect the autotransformer:

Perform

a visual inspection of the autotransformer to check for any visible damage,

loose connections, or signs of wear. If you notice any issues, do not proceed

with the installation or operation and contact a qualified technician. 5. Connect the

autotransformer: Make the

necessary electrical connections as per the manufacturer's instructions. This

typically involves connecting the input and output terminals of the

autotransformer to the appropriate power sources and loads.

5. Connect the

autotransformer: Make the

necessary electrical connections as per the manufacturer's instructions. This

typically involves connecting the input and output terminals of the

autotransformer to the appropriate power sources and loads.  6. Set the taps: Autotransformers often come with

multiple tap settings to adjust the output voltage. Select the appropriate tap

based on your system requirements. This may adjust a physical switch or use a

control panel if the autotransformer has an automatic tap changer.

6. Set the taps: Autotransformers often come with

multiple tap settings to adjust the output voltage. Select the appropriate tap

based on your system requirements. This may adjust a physical switch or use a

control panel if the autotransformer has an automatic tap changer. 8. Test the

autotransformer: After making

the connections, perform tests to verify the autotransformer's functionality.

Check for proper voltage regulation, phase balance, and any other parameters

relevant to your specific application. Please follow the manufacturer's

instructions.

8. Test the

autotransformer: After making

the connections, perform tests to verify the autotransformer's functionality.

Check for proper voltage regulation, phase balance, and any other parameters

relevant to your specific application. Please follow the manufacturer's

instructions. 8. Monitor the

autotransformer: During

operation, keep an eye on the autotransformer for any signs of abnormal

behavior, such as excessive heat, unusual noises, or voltage fluctuations.

Continuous monitoring helps detect potential issues early and prevent major

failures.

8. Monitor the

autotransformer: During

operation, keep an eye on the autotransformer for any signs of abnormal

behavior, such as excessive heat, unusual noises, or voltage fluctuations.

Continuous monitoring helps detect potential issues early and prevent major

failures. 9. Maintenance and

periodic inspections: Follow

the manufacturer's recommended maintenance schedule to keep the autotransformer

in optimal condition. Perform regular inspections, cleaning, and any necessary

adjustments or repairs as per the guidelines.

9. Maintenance and

periodic inspections: Follow

the manufacturer's recommended maintenance schedule to keep the autotransformer

in optimal condition. Perform regular inspections, cleaning, and any necessary

adjustments or repairs as per the guidelines.