Toroidal Transformer Basic

A transformer is an electrical device that is used to transfer electrical energy from one circuit to another circuit through electromagnetic induction. It consists of two coils of wire, known as primary and secondary coils, which are wound around a common magnetic core.

There are many kinds of transformer, toroidal transformer is one of them. In this atricle, we will introduce some basic knowledge of toroidal transformer.

A toroidal power transformer is a type of electrical transformer that has a toroidal (doughnut-shaped) core made of a ferromagnetic material, such as iron powder or silicon steel. The primary and secondary coils of wire are wound around the core, with the primary coil connected to the input voltage source and the secondary coil connected to the output load.

One of the main advantages of a toroidal transformer is its compact size and shape, which allows for efficient use of space in electronic equipment. The toroidal shape also reduces the amount of magnetic flux leakage, which can cause electromagnetic interference with other components in the equipment. This results in a transformer with high efficiency, low noise, and low electromagnetic radiation.

Advantages:

- Volume and Weight. All windings in a high voltage toroidal transformer are symmetrically spread over the entire core which makes the wire length very short. A higher flux density is also possible as the magnetic flux is in the same direction as the rolling direction of the grain-orientated core, allowing significant savings of volume and weight. A higher current density can flow through the wire as the whole surface of the toroidal core allows efficient cooling of the copper windings. This smaller size makes it more useful for compact electrical products.

- Efficiency. The ideal magnetic circuit of the toroid, together with the ability to run at higher flux density than E-I laminates, reduces the number of turns of wire required and/or the core cross-sectional area. Either benefit reduces losses.

- Transformer Hum. Audible hum is caused in transformers when the windings and core layers vibrate due to the forces between coil turns and core laminations. Moreover, the hum increases over time as the laminations start loosening. But the construction of toroidal transformers helps to dampen acoustic noise. The core is tightly wound, spot welded, annealed, and coated with epoxy resin or insulated with Mylar tape. The uniform winding of the core leaves no air gaps, thus leaving no loose sheets to vibrate, ultimately resulting in less hum.

- Stray Field. Stray field in toroidal transformers is approximately 85-95% lower than in conventional laminated transformers. Achieving low levels of stray field is an important consideration for the equipment designer as the phenomenon can create unwanted noise through interference with sensitive electronics. A toroidal transformer will generally offer a reduction of 8:1 in magnetic interference levels compare with traditional frame style laminate types.

- Dimensional Flexibility. Toroidal transformers offer a high degree of dimensional flexibility compared with conventional laminated transformers. Toroidal cores can be produced in virtually any diameter or height.

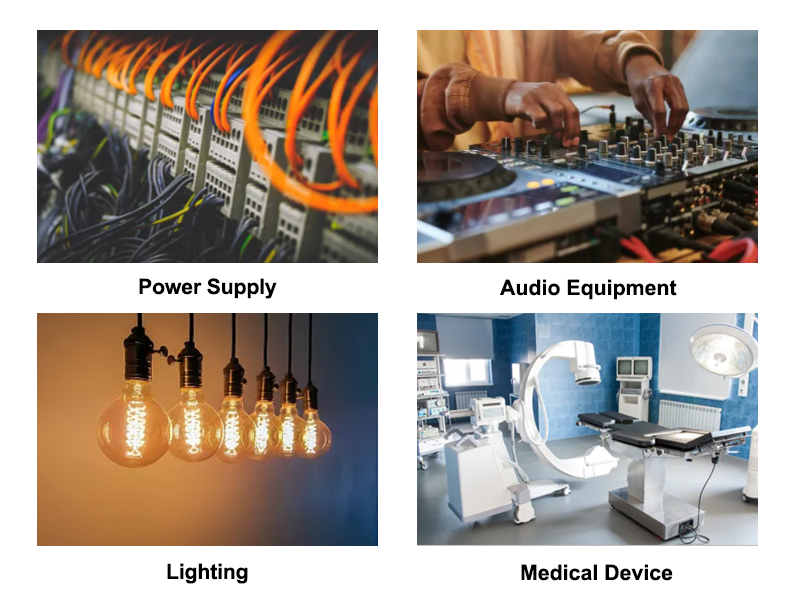

- Power Supply. Toroidal transformers are widely used in power supply applications. They are used to convert the high-voltage input to the low-voltage output required by electronic devices.

- Audio Equipment. Toroidal transformers are used in audio equipment, such as amplifiers and mixers. They help to reduce noise and interference and provide a clean power source for the audio equipment.

- Lighting. Toroidal transformers are used in lighting applications, such as halogen lamps and LED lights. They are used to convert the high voltage input to the low voltage required by the lighting source.

- Medical Device. Toroidal transformers are used in medical devices, such as MRI (nuclear magnetic resonance imaging) machines and X-ray machines. They provide a clean and stable power source for these devices.

Toroidal transformers are very popular with home and office users due to their compactness, small size and light weight, making them easy to install in space-constrained environments, while providing high energy efficiency and low noise. Buy a toroidal transformer and experience the various conveniences it brings!